CMMS | Software for maintenance control and administration

MP maintenance management

The maintenance management platform for service companies

MP maintenance software helps you increase productivity, reduce downtime, automate your maintenance operations, achieve certifications, and more.

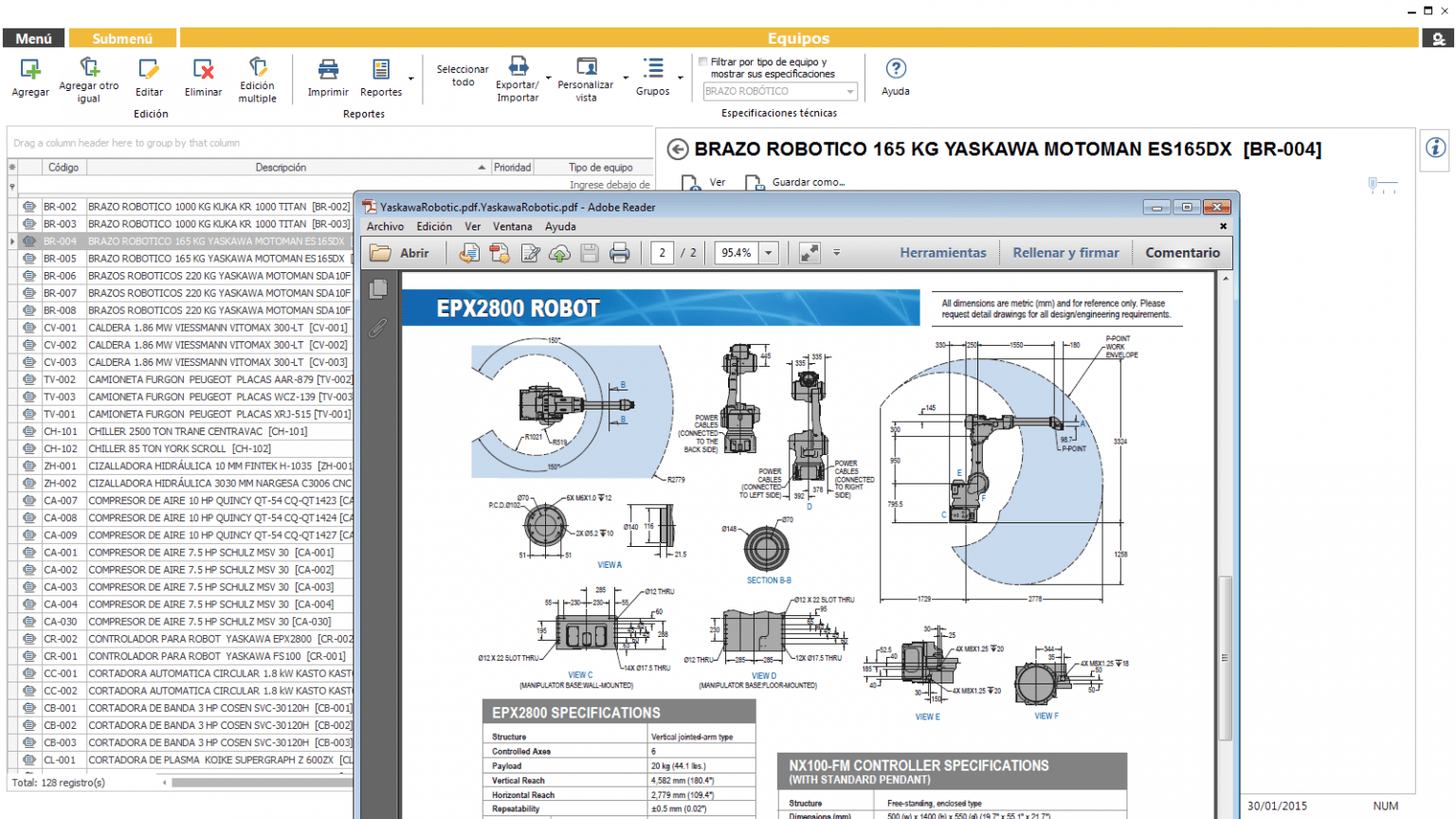

Complete Documentation Of Company Assets.

Document in the maintenance management program all the information about your assets such as technical data, maintenance plans, spare parts, supplier data, images, plans, diagrams, videos, location, guarantees, etc…

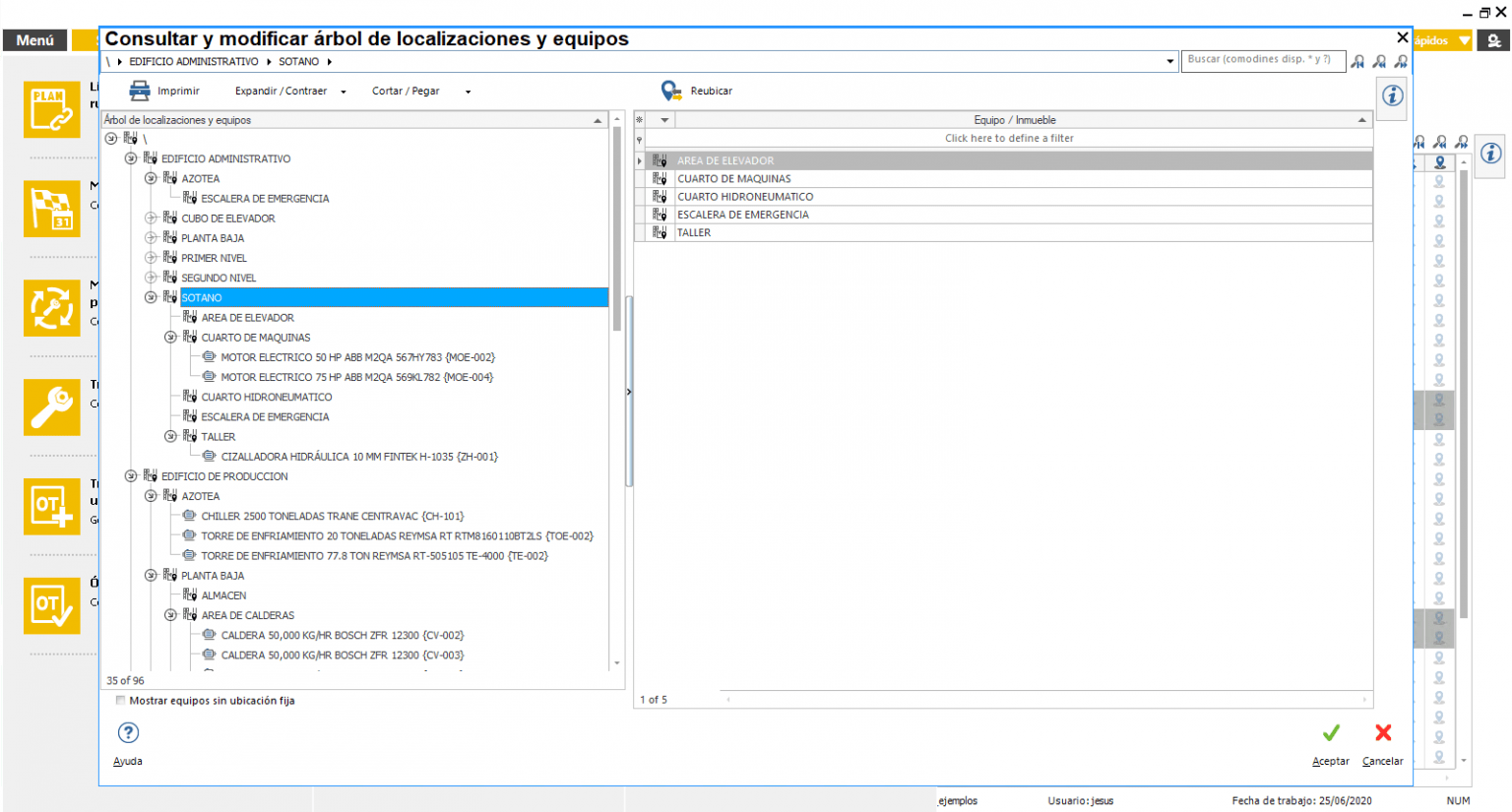

Tree Of Locations, Parent Computers And Child Computers

In version 10, the visualization of parent computers and child computers within the tree is incorporated into the location tree, allowing a complete overview of all the company’s assets and their respective locations to be displayed.

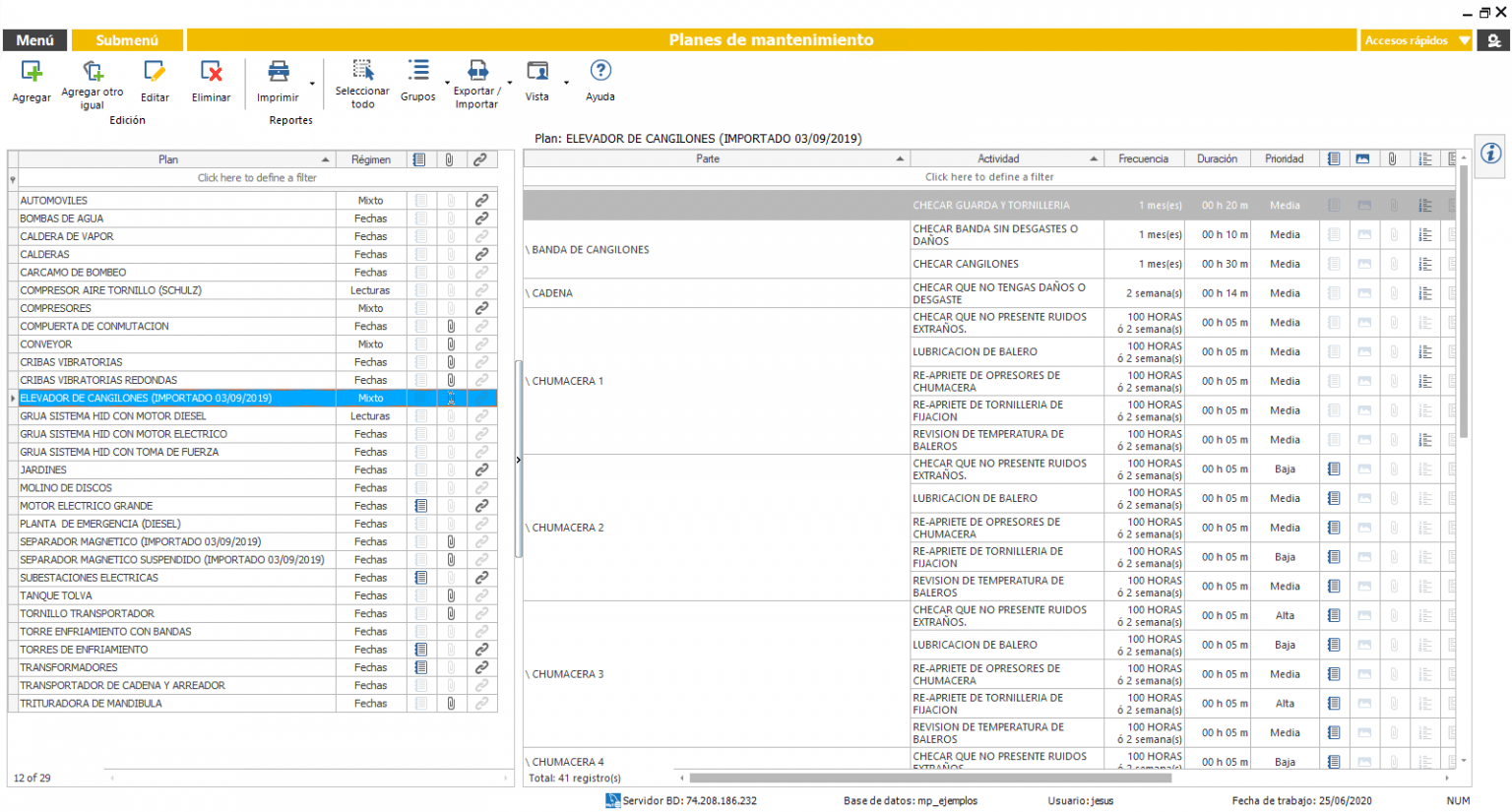

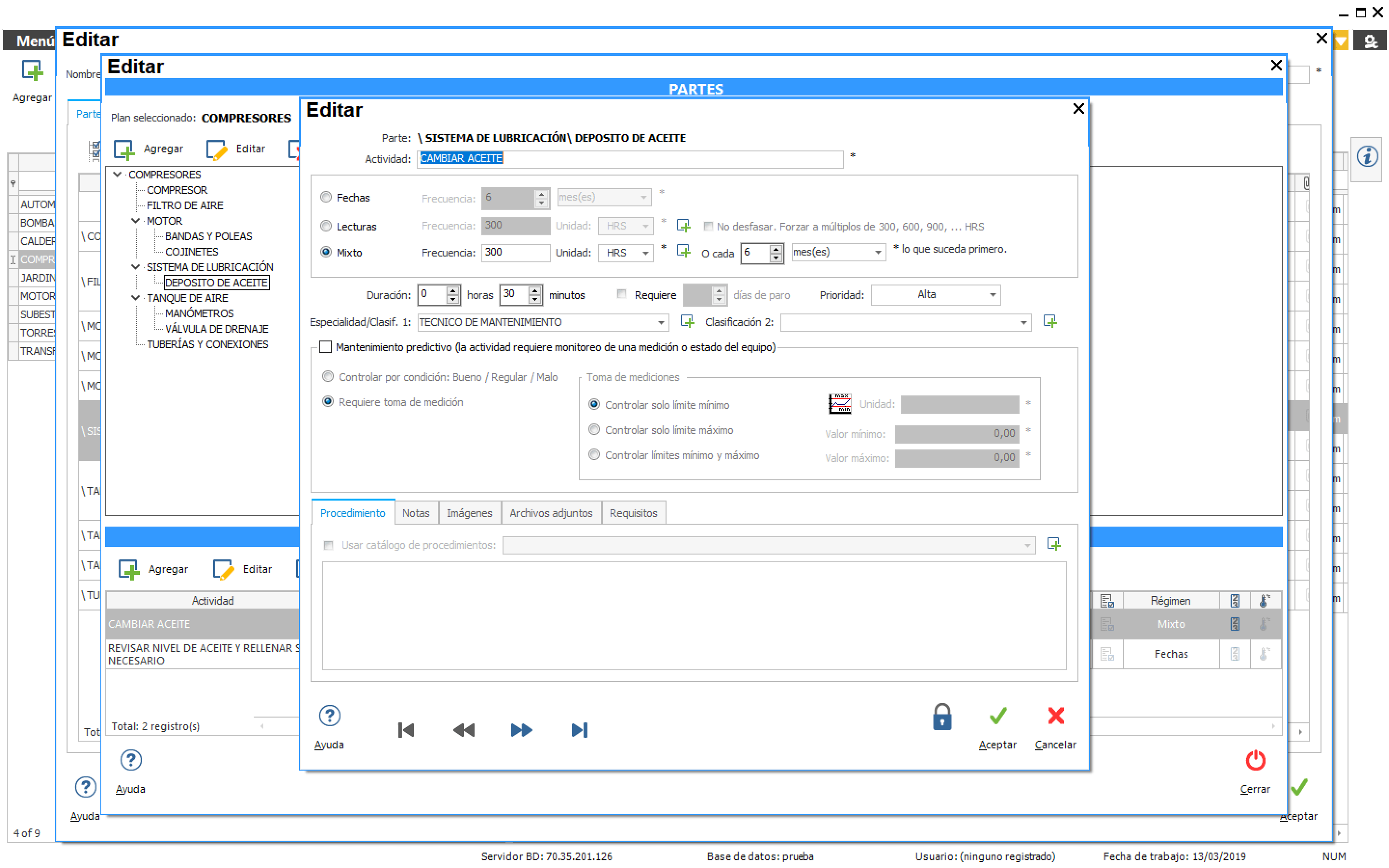

Maintenance Plans And Schedules

Document your maintenance plans or routines with information regarding routine maintenance activities that must be performed on equipment and locations, as well as the frequency with which each activity must be performed. Maintenance calendars graphically show the scheduling of maintenance work, indicating the dates on which said work must be carried out. Every time the user reports to the PM about routine work performed, the PM reschedules the next date when it needs to be done again, automatically adjusting maintenance schedules.

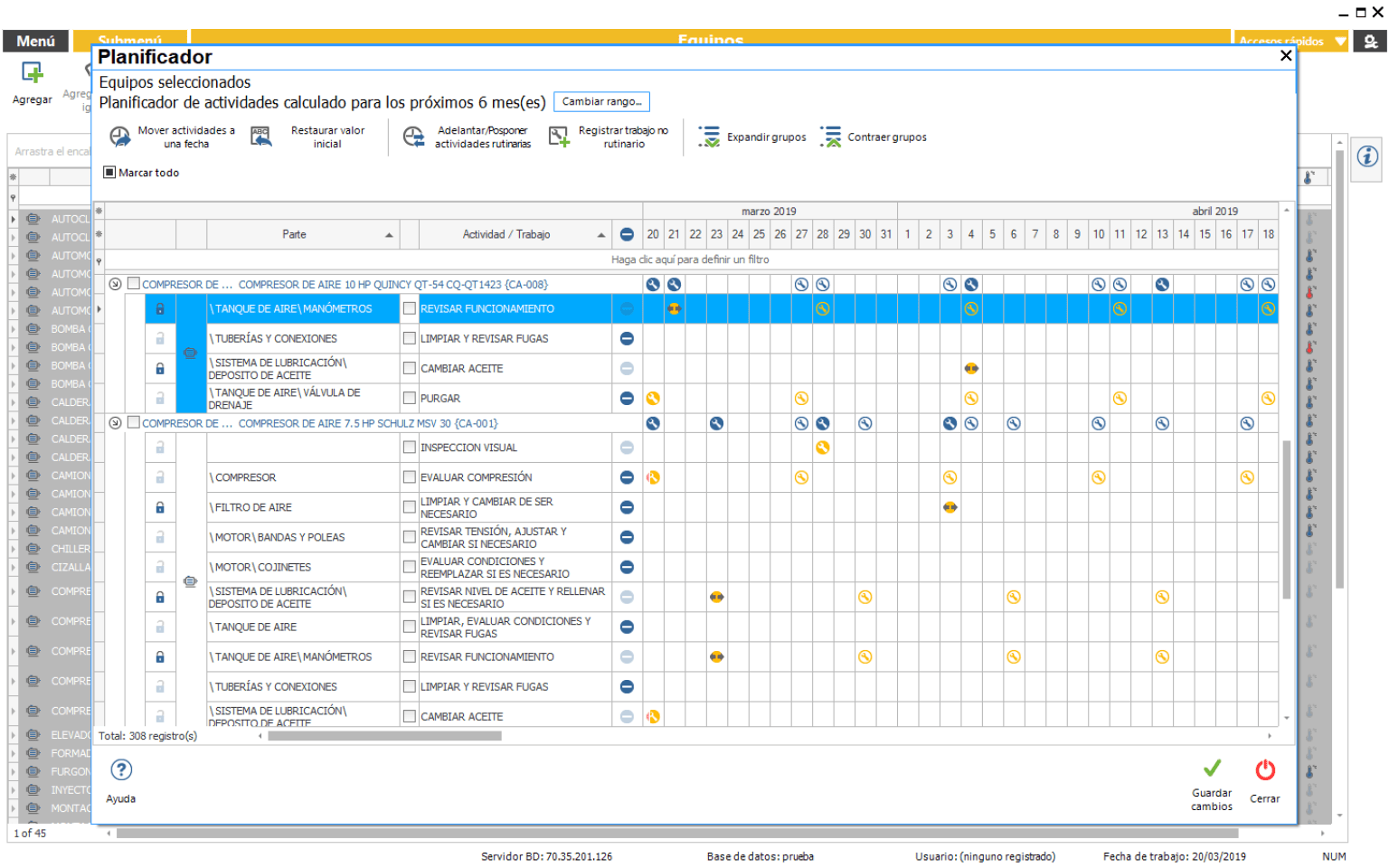

Planner

Use the drag and drop tool to advance and postpone maintenance activities on the detailed maintenance dashboard with surprising ease. Without a doubt, a tool that makes maintenance management easier.

Maintenance Activities Controlled By Dates Or Readings, Whichever Comes First

In date-based maintenance activities, the frequency with which the activity must be performed is established based on the elapsed time. (Example, daily, every week, every 15 days, every 3 months, every 2 years, etc.)

In controlled maintenance activities based on readings, the frequency with which the activity must be performed is established based on the use of the equipment. (Example, kilometers traveled, hours of use, units produced, number of ignitions, cycles, etc.)

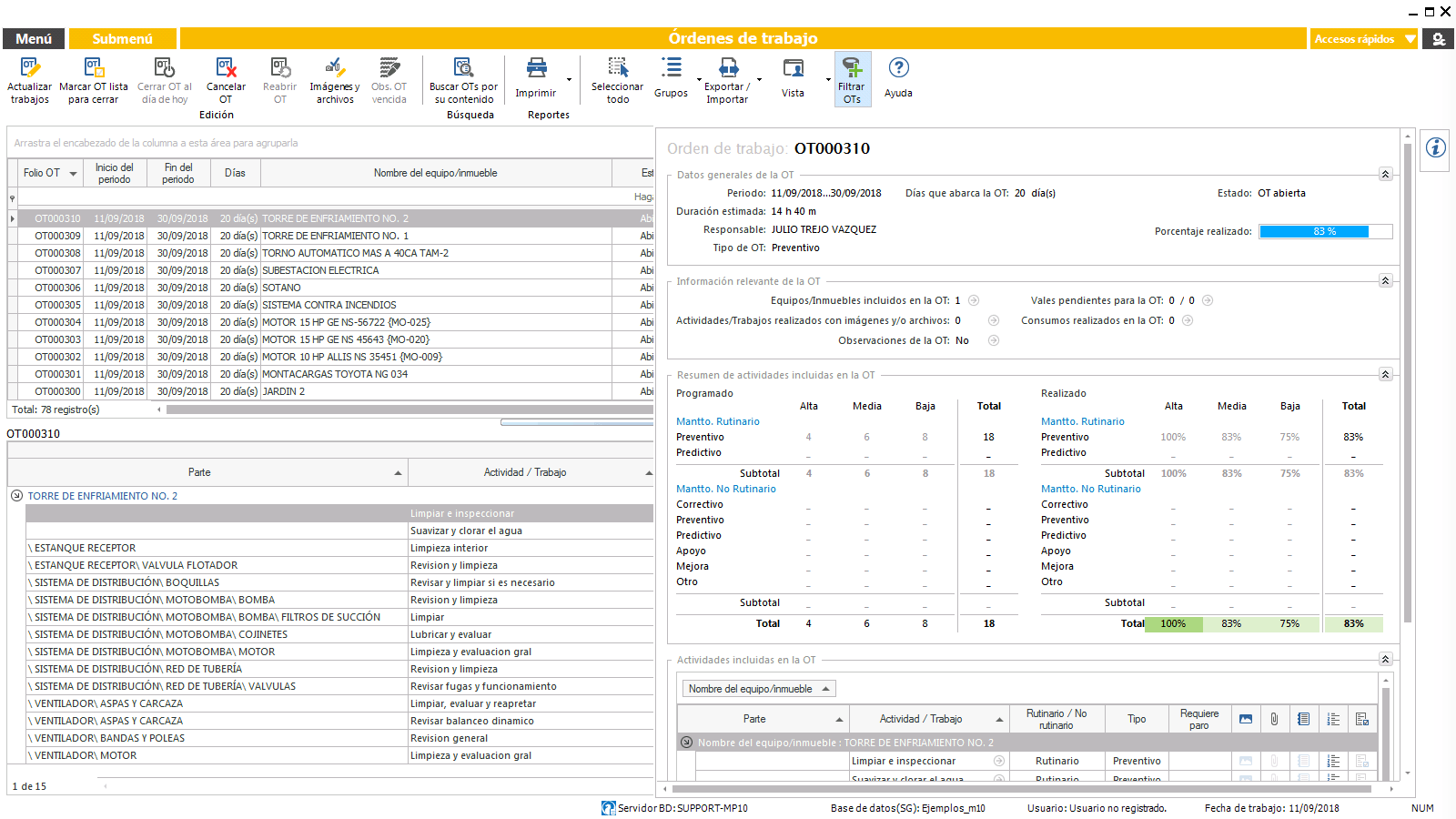

Generation, Administration And Monitoring Of Work Orders

An important improvement in version 10 can be found in the work order generation process, which is now much more versatile, intuitive and easier, with different routes or paths from which you can generate your work orders.

Once your work orders have been generated, in this module you can consult, print, update the work performed and close your completed work orders.

In addition, you can assign the person responsible and register the spare parts, consumables and external services that you have used.

As your software partner

TOPS wants to make sure you get the most out of your software investment

“TOPS Software Maintenance and Support Plan (Maximum Value Plan) subscribers are eligible to receiving up to 8 man-hours of personalized software training each year.”